APR 8-10 2025

Aviation Week MRO Americas 2025

Atlanta, GA

News and events

APR 8-10 2025

Aviation Week MRO Americas 2025

Atlanta, GA

The prestigious MRO Americas convention this year marked a special milestone — it took place right in our headquarters’ hometown of Chicago for the first time in its 29-year history. Our collective Technical Operations team did a fantastic job engaging in supplier meetings and discussions with attendees and exhibitors, forging stronger connections across the industry.

Tech Ops SVP Maria Deacon delivered the hometown airline address with key messages around safety as the foundation of our culture, collaboration on best practices across our industry, and the importance of training and mentorship for all our employees.

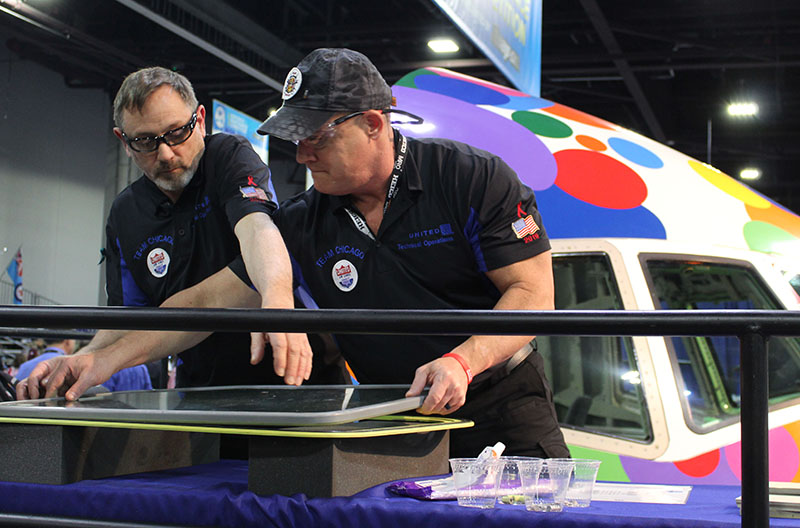

Amidst the week’s buzz, April 11 stood out as the pinnacle, with the Aerospace Maintenance Competition (AMC) hosting an awards ceremony to honor the best among the more than 600 professional and student aviation maintenance technicians putting their skills to the test.

Our all-women team, Chix Fix, secured second place in the Commercial Aviation category. The Chix Fix team are pioneers in encouraging more women to join the aerospace maintenance field and the competition itself. This is their last appearance as an all-female team and was a poignant moment, celebrated by both colleagues and spectators. Going forward, they will be teaming up with their male colleagues to field more co-ed teams.

Our Line Maintenance team from CLE (Cleveland) and ORD clinched third place in the same division, with our combined Base/Line team from IAH also claiming third in their category (MRO/OEM), and the accolades didn't stop there.

Chix Fix and Line were also contenders for the prestigious William O'Brien Award, which recognizes the team with the highest overall scores. Our CLE Line team had previously won this award for three consecutive years, showcasing our consistent excellence.

Among other standout moments, ORD Maintenance Control Tech Senior Staff Representative Heather Behrent from Chix Fix won the highly distinguished Professionalism Award, earning applause and admiration for her exceptional performance. This award, based on judges' votes across the various events, highlighted our team's dedication and professionalism.

United's support for the AMC extended beyond participation, as we sponsored A&P schools, with our mentored teams all doing well. And, we sponsored and judged two of the 27 events in the competition. Our three teams swept the top three spots in each of those events.

Throughout the conference, our United leaders seized the opportunity to strengthen relationships, participating in panels and sessions that explored the future of aerospace maintenance and innovation.

As the event concluded, Maria reflected on the outstanding success of the conference and the remarkable achievements of our technicians.

“The AMC isn’t just about competition, our strong showing is a testament to our commitment to safety, collaboration, and pushing boundaries in the aerospace industry,” she said.

Three teams of United aircraft technicians are getting ready to compete against, and bond with, hundreds of people their peers from around the world in the annual Aerospace Maintenance Competition (AMC).

This year, for the first time ever, United teams will take the field in Chicago.

The AMC will take place April 9-10 at McCormick Place as a featured event during the massive MRO Americas conference. With 16,000 attendees, this is the largest annual gathering of aviation maintenance professionals; from operators, and manufacturers to the maintenance, repair and overhaul (MRO) industry. Our very own Tech Ops SVP Maria Deacon will be a featured speaker.

United will field three teams for the AMC, and each one also sponsors a team from an aviation maintenance school.

“We feel we have accomplished what we set out to do when we formed the team,” Laura said. “The AMC will have six all-female teams this year! We have a ways to go, but we have made progress, and our team is very proud that they have been a part of that progress. We will continue to encourage women to become aircraft maintenance technicians. We hope that in the future, United will continue to sponsor the AMC with a new direction of fielding mixed teams within United.”

United also sponsors and staffs two of the 27 events in which the techs will compete — Fuel Tank Entry, done under a repurposed Boeing 747 wing, and, new this year, Render Safe, using a Boeing 767 cabin door and adjacent fuselage section. Both were constructed and are maintained by a team in IAH led by Assistant Manager Fred Glau. Fred and Avionics Technician Scott Cole, Lead Sheet Metal Technician Paul Davis, Lead Avionics Technician Doug Richey, Shift Manager David Shore and Avionics Technician John Vasquez will judge the events at the AMC.

All AMC events are timed but speed is secondary to safety and compliance. Time is added as a penalty for any deviations from the task cards or for not following all safety guidelines. Final times determine first, second and third place for each event, and the top three teams in each will be honored at an awards ceremony on April 11. The team with the best overall score wins the Bill O’Brien Trophy. United also presents the Competing with Professionalism Awards to top school teams.

In addition to Maria Deacon, who is the first woman to serve as United Tech Ops SVP, speakers at MRO Americas include Tech Ops Safety and Compliance VP and Chief Engineer John Wiitala, Calibrate Managing Director Simone Drakes, Maintenance Training Director Rick Brown and Digital Fleet Management Director Luke Meminger. Dozens of other United leaders will also attend meetings with business partners and suppliers and network with peers.

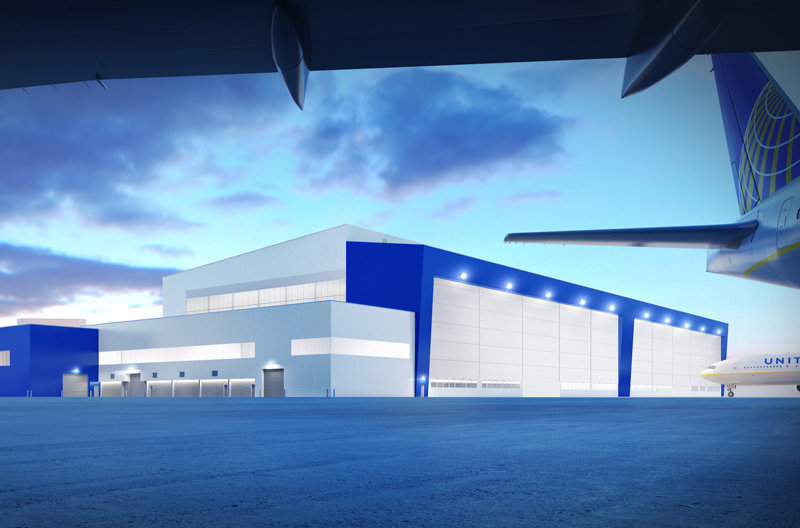

It’s been a long time coming, but our PDX (Portland, Oregon) Tech Ops team finally has a hangar, and it’s a beauty.

Various delays in approvals during renovation and construction, and then the pandemic, kept pushing the opening date down the calendar.

Aircraft Maintenance Senior Manager Paul Troike and his team of 65 technicians and their other Tech Ops colleagues in Facilities and GSE Maintenance, Inspection and Stores, were finally able to start working in the safe and new hangar just a few weeks ago. On April 2, the team hosted the ribbon-cutting ceremony for which they have waited so long. They also used the event to celebrate earning their Silver Safety certification in United’s Safety Excellence Program last November.

“This is a great working environment,” Line Maintenance VP Rodney Luetzen told the crowd of employees, their family members and visitors. “Look at the fall protection, the flooring, the lighting, the fixtures — safety is at the core of what we do, so it is fitting that we recognize this team’s excellence in safety along with opening this beautiful facility.”

Earlier, SFO Maintenance Hub Managing Director Chris Carrick noted how the PDX team had compiled a superlative safety record while working outdoors and handling a steady stream of through flights, RON aircraft, narrowbody A checks and recovering out-of-service aircraft while compiling outstanding performance and safety metrics.

“The Portland team has had no aircraft damages since 2017,” Chris said. “That’s 2,556 days and is an amazing accomplishment.”

Tech Ops SVP Maria Deacon and others noted how many employees brought their family members to the ribbon-cutting to share in the excitement and show them around their new workplace.

“I can really feel it when I come here, that this team is a family,” Maria said. “Everybody who is part of this organization should feel proud right now. And get ready because we’re going to send a lot more work your way!”

Paul also thanked the many groups and people at United — particularly Corporate Real Estate, Airport Operations, Finance and Government Affairs, among many others — and the Port of Portland, and singled out Rodney for keeping the project moving through upper leadership, even in times of uncertainty about our future. PDX Line Technician Sean Fisher and Quality Control Aircraft Inspector Tuan Tran wielded giant scissors to join representatives of the aforementioned groups to cut the ribbons and the long wait was finally over. Congratulations to PDX Tech Ops, and thanks to everyone who helped put them under the roof they have earned through safety, operational excellence and patience.

United Next growth may be perceived by many as only being made up of the arrival of hundreds of new and refurbished aircraft, creation of thousands of new career opportunities, and regular announcements of exciting new travel destinations and so on. But another vital yet possibly overlooked ingredient to the success of United Next is the dramatic growth of Tech Ops.

This growth includes employees, facilities, aircraft and capabilities. The expansion is to not only accommodate the fleet volume, but also to spread out our capabilities to provide advanced services in more locations, which will enable far more efficient scheduling and provide quicker response to issues.

Since the launch of United Next in 2021, we have opened new Line Maintenance stations at ABQ (Albuquerque, New Mexico), BNA (Nashville), CLT (Charlotte, N.C.), DTW (Detroit), JAX (Jacksonville, Fla.), MCI (Kansas City, Mo.), OMA (Omaha, opening July 30), RDU (Raleigh-Durham, N.C.,) and RSW (Fort Myers, Fla.). Two more will open later this year — DSM (Des Moines) and SLC (Salt Lake City). Combined, these new stations have already added more than 250 positions, mostly frontline technicians.

Tech Ops has hired more than 2,000 new frontline employees so far this year and just opened a centralized Training Center at IAH for new hires to receive a common orientation and initial training before heading off to their assigned stations. Eventually, that center is envisioned to expand for use by the whole department for recurrent training.

Tech Ops is also shifting some A Checks (frequent, regular light checks that occur on every mainline aircraft) and other scheduled tasks to stations such as LAS (Las Vegas), PHX (Phoenix) and SAT (San Antonio). Improvement projects are happening at hubs, too. LAX and ORD are expanding or planning expansions of their EBU (engine build-up) shops to support engine changes.

To further support our United Next growth, we are increasing our capabilities in other locations within our global network. Earlier this month, Tech Ops cut the ribbon on a renovated hangar at GIG (Rio de Janeiro), our first outside the United States. We have added additional A Check capacity and staff at LHR (London Heathrow), MEX (Mexico City) and TPE (Taipei), and plan to expand our capabilities at GRU (São Paulo). We also are in process of renovating a hangar at LHR that will become our second outside U.S. territory.

Just as the new GIG hangar includes a larger warehouse, our Supply Chain department has also added a new distribution center in AMS (Amsterdam) to facilitate quicker movement of parts in Europe. Additional distribution centers are planned or under development at GIG, IAH and SYD (Sydney).

At GIG for the July 13 ribbon-cutting, Tech Ops SVP Maria Deacon and United EVP and Special Advisor Greg Hart were among a small group of special guests, which also included airport CEO Alexandre Monteiro, other local officials, contractors and suppliers.

The stars of the show, however, were our local Tech Ops employees. The team is led by Brazil Aircraft Maintenance Senior Manager Jose Lisboa and falls under our Airframe Overhaul and Repair department, along with our base at IAH. The team has grown from a few dozen to several hundred over the past year while servicing United aircraft on the ramps while the hangar, which we secured when another carrier moved out, was renovated. They successfully completed their first A Check on Jan. 5, 2023.

“Our Rio team has already proven themselves admirably,” said Airframe Overhaul and Repair Managing Director Don Klaus. “I’m confident they will continue to thrive and perform excellent work now that the hangar is complete. It’s been a long and challenging year building up to this, and they have performed consistently great through it all.”

“The energy from our Brazilian team was contagious,” added Maria after the GIG event.

The ribbon-cutting was followed by a very casual open house, but organizers found time to include a special way to honor Greg, a former Tech Ops SVP who also led our United Next effort as Chief Growth Officer during its critical formative years. A plaque was unveiled in the hangar’s new conference room, which is now officially dedicated to Greg.

On behalf of the GIG teams, Jose also presented Greg and Maria with personalized, scale models of the new hangar; two more were personalized for Don and for Tech Ops Planning & Strategy VP Kurt Carpenter, whose Planning and Strategy department includes our Airframe bases and oversight of our repair vendors.

May turned out to be a challenging month for major repair projects which required support from the OSV and Structures Engineering teams. Although challenging, the projects were no match for great teamwork, which minimized the impact to the hangar plan and allowed both aircraft to be returned to service to support the summer schedule.

During a mandated Airworthiness Directive (AD) inspection at EWR, aircraft 201 was found with a cracked frame. The aircraft was ferried to RFD for a special hold for the replacement of BS STA 663 LH and RH frames. Structures Engineering and ESC OSV Engineering teamed up to tackle the replacement of these major structural components.

Increasing the complexity of the replacement was the fact that Boeing has not yet released the Service Bulletin that contains the replacement instructions. So, in their usual way of thinking out of the box and determination to solve a problem, the group used high-level instructions from Boeing and utilized various Boeing production drawings to facilitate the replacement. Of course, engineering issued our final approved paperwork with the instructions. Great work!

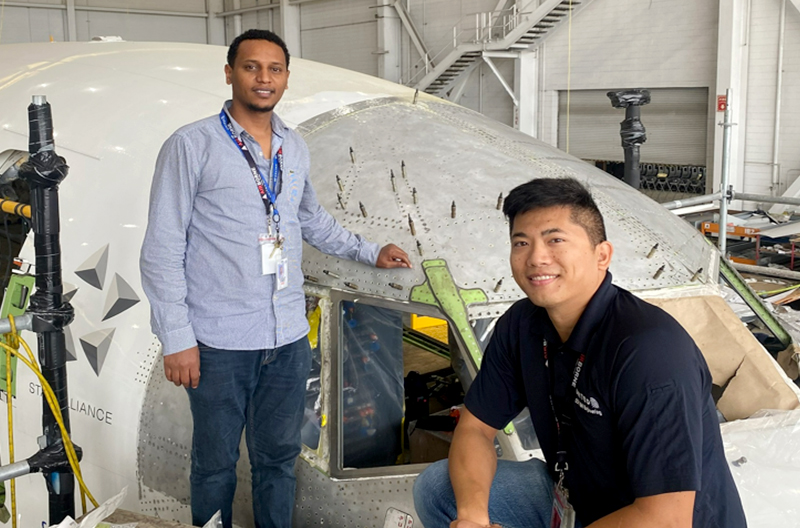

We also had aircraft 413 in TPA for its D-check that had two Deferred Item Projects (DIP) to replace the #3 LH and RH window frames (seen below). Big thanks to ESC Engineers Yussuf Ahmed (pictured above, left) and Tim Vo (pictured above, right) who traveled to TPA to provide on-site support for this project. This was the first 737 window frame replacement for United and for our OSV MRO partner.

Congratulations are in order for the three teams who represented United at last week’s Aerospace Maintenance Competition (AMC) in Atlanta! United has taken part for several years now and has a legacy of wins and excellence, and this year was no different. Competing against over 80 other teams, ours brought home three overall category awards, including one first, and 19 individual event places, including eight first-place wins! The competition is held annually in conjunction with Aviation Week Network’s MRO Americas trade show. AMC is an annual event where teams representing schools, commercial airlines, repair and manufacturing companies, military, general aviation and space compete, learn from one another, and find out who's the best of the best. The competition tests the skills of technicians in 26 rigorous events, such as airframe damage inspection, composite repairs, tire inspections, cable rigging and more.

Our three teams consisted of: Chix Fix, Line Team, and the Base/Line Team.

The Line team took top honors in the Commercial category, besting Alaska Airlines for first place. They also won second in total points for the entire competition overall and medaled in eight individual events, winning one. The Base/Line team came in second place in the Maintenance, Repair and Overhaul/Original Equipment Manufacturer (MRO/OEM) category, finishing in the top three in seven events and winning five. Chix Fix medaled in four individual events, taking first in two of them.

“This was a great year for our teams,” said Line Maintenance VP Rodney Luetzen. “They demonstrated their incredible talent, hard work, and commitment to what they do.”

As part of our commitment to train and hire the next generation of aircraft maintenance technicians, each United team also sponsored a student-led team. The schools sponsored this year included one team from Lewis University in Illinois and two teams from MIAT-Houston's College of Technology. Chix Fix mentored the MIAT all women’s team, the Lady Mustangs. Not only does United’s sponsorship enable the students to attend the competition, but it also gives them unique insight to see what it’s like to work for a global airline and train side by side with seasoned, licensed AMTs.

“The schools we’re working with this year are awesome, and several of them have received contingent offers to join the team,” Jack, Line team coach, said. He added that to prep for the competition, the students are brought to a United hub where they train with them for a week. “We’ve had a great time with them this year,” he said. “It’s a great exposure for them to us and the airline.”

Rodney agreed. “These United team members are role models, and the students they mentor are watching,” he said. “They are leaders in their craft.”

At the awards ceremony Thursday morning, two members of the Chix Fix presented the prestigious Competing with Professionalism Award, an honor United gives annually to student-led teams at the competition.

This award is presented to the school team who exhibited the greatest level of professionalism during the competition and the team that exhibited true sportsmanlike conduct at all times.

After they observe the competition, event judges submit their votes for which teams best exhibited this behavior. But this year, there was a twist: it will now be renamed as the John Goglia Competing with Professionalism Award. A nod to his many years of contribution to our industry, John currently serves as the president of the Aerospace Maintenance Council, the organization responsible for hosting and organizing the AMC. The 2023 John Goglia Competing with Professionalism Award was given to two deserving school teams: MIAT College of Technology Team 2 and Salt Lake Community College.

“The award has John’s name on it for a reason,” Rodney said later.

With more than 40 years of experience in the aviation industry, 20 of them as an aircraft technician at United, John was the first and only Airframe and Powerplant mechanic to receive a presidential appointment to the National Transportation Safety Board (NTSB). He served from August 1995 to June 2004. He quickly distinguished himself in numerous areas of transportation safety and was instrumental in raising awareness of airport safety issues, including the importance of airport crash fire and rescue operations and the dangers of wildlife at airports. He was involved for more than 20 years as a union flight safety representative on accident investigation teams.

In addressing our teams privately, John talked about how proud he was of United’s efforts and offered encouragement.

“Mechanics push hard and don’t let obstacles get in your way,” he said. “We all have a bit of Charlie Taylor in us,” referring to Charles E. Taylor, aircraft mechanic for the Wright brothers and the namesake of the Charles E. Taylor Master Mechanic Award.

Full event results can be found on the AMC website. The 2024 competition and MRO will be held from April 9 - 11 in Chicago.

Our Tech Ops team at LAX, like those at most of our primary maintenance locations, relies on an Engine Build-Up (EBU) shop in the hangar to handle complicated off-wing work, such as mating new sections to other powerplant components during an engine change.

If we need to change an engine elsewhere, we can usually arrange for a suitable on-site EBU location. But a lack of available hangar space last month in SYD (Sydney) prompted our teams to figure out a solution. Here’s how great teamwork and improvisation led to a successful outcome.

After one of our Boeing 787-9s landed safely in SYD on March 21, a status message indicated that the oil debris monitoring system (DMS) detected material on the magnetic chip detector on the #1 engine. A sample was sent to our SFO Metallurgy Lab, which found that the material came from bearings. TOMC (Tech Ops Maintenance Control) then reached out to the team in LAX, where a GEnx engine was available.

This became the first “off-field” engine change on a Boeing 787 for United, and a noteworthy one at that. The GEnx engine propulsor section was shipped from LAX to SYD, with the build-up needing to be done there. We were able to retain the original engine’s fan/stator, or forward, and exhaust, or aft, sections, as both were unaffected by the DMS finding.

Once the LAX team and two powerplant engineers arrived and joined forces with our SYD Aircraft Maintenance crew, and tooling and parts arranged by the AOG team cleared customs, a sturdy tent was erected planeside to serve as a “pop-up” EBU shop. The team lowered and disassembled the old engine, built up and installed the new engine, made all the many necessary connections, then conducted engine runs and operational checks.

The aircraft ferried back to the United States and returned to service, with the work completed a full day earlier than expected. LAX Aircraft Maintenance Shift Manager Jose Montes, who led the field trip along with Supervisor Fernando Melendez, said the engine change went smoothly thanks to an exemplary “working together” attitudes by both the host and visitor maintenance teams. Also, the techs had great support from the on-site engineers and the SYD Airport Operations leaders, as well as the great planning and ongoing remote support from TOMC and the AOG teams. Jose also thanked Tech Ops colleagues back in LAX and DEN who were instrumental in helping set up parts and tooling quickly so they could be shipped out to SYD.

Our new LAX Technical Operations Center (LAXTOC; LAX’s new hangar complex) was recently awarded LEED Gold certification upon achieving 60 points on the U.S. Green Building Council’s LEED scorecard.

The hangar project was required to achieve LEED Silver in accordance with LAWA’s (Los Angeles World Airports) policy. However, the project team went above and beyond by achieving the next certification level higher – Gold.

Completion of this project and achievement of the certification is another tangible example of our leadership in sustainability.

Some of the categories on the LEED scorecard in which we were able to achieve points include location and transportation, the sustainability of the site, water and energy efficiency, materials and resources (always recycling!) and indoor environment quality.

“As a company, we are committed to holistically addressing our impact on the environment, not only in the air, but on the ground and in the communities in which we operate,” said Environmental Sustainability Director Frannie Levar. “This facility is a tangible example of our commitment to our climate ambitions, and prioritizes water efficiency and conservation, energy use reduction, and indoor environment quality, among others.”

The LAXTOC is a state-of-the-art facility that our employees can be proud to work in, while also a sustainably designed facility that they can feel good about occupying.

“Our team continues to leverage projects within our vast real estate portfolio to further our commitment to sustainable design,” said CRE Planning and Development Regional Director Kaveh Dabiran. “Our goal is to deliver environmentally conscious facilities that will promote the well-being of our employees.”

Congrats to the working project team who helped earn this incredible achievement!

Our three teams in the 2022 Aerospace Maintenance Competition performed admirably, made a lot of new fans, were collectively perhaps the most popular airline contingent at the event held in Dallas April 26-27, and made multiple trips to the podium to thunderous applause from their peers during the awards ceremony on April 28.

The Line Maintenance team of CLE and ORD technicians had the highest overall finish for United, coming in third in a very competitive commercial airline category, and our all-female Chix Fix team took home the coveted “Peer Team” title. That award is based on the votes of each of the 71 teams who vote for the one group they admire most and would want to work alongside.

Line, the Chix Fix and our IAH Base team, who competed in the MRO (maintenance provider) category, each made multiple trips to the stage to pick up some of the event trophies based on performance in the 27 individual skill events that make up the competition.

The AMC is as much about fellowship and mentoring as it is about collecting trophies, and working alongside students and getting them interested in careers with United Tech Ops is a big part of our presence in this annual event, which was not held in 2020 or 2021 due to the pandemic. The Chix Fix sponsored West L.A. College, which did extremely well, finishing second overall of all the school teams entered.

Here are the events for which our teams won the top prize: IAH Base took Transparencies and Engine Fan Blade Removal, the Line team won Clearance Control Valve/Bleed Valve Solenoid Tests and Flex Fluid Lines, and Chix Fix won External Power Receptacle, Handheld Bond Meter Test and Aircraft Tire Inspection. Teams that sponsor and judge events defer their prizes if they win those events to the next closest finisher, but based on scores alone, United teams also won the Fuel Tank Entry Precautions and Cable Rigging events we sponsored. And, the MIAT-Houston school team sponsored by our IAH team was the winner in the Fuel Tank Entry Precautions event.

Congratulations to our teams and all the winners and competitors!

It has been a long wait for United Tech Ops to defend the title “best aircraft technicians in the world” that we earned three years in a row from 2017-19, at the Aerospace Maintenance Competition (AMC) thanks to the extraordinary performance by our CLE Line Maintenance team. Later this month, we are fielding three teams with hopes of carrying forward that remarkable streak after a two-year hiatus.

The competition, which includes more than 80 teams, is a featured event of the MRO Americas conference, but was not held in 2020 or 2021 because of pandemic restrictions. In addition to defending the overall championship, our teams will seek to medal in each of the 27 competition tasks, and this year will have the added incentive of going up against a lineup of six teams fielded by a certain competitor airline based in the conference city, Dallas, Texas.

Our participation in the AMC goes beyond the awards ceremony at the end of the three-day tournament – as part of our recruitment efforts, we are sponsoring teams from three aviation schools with which we already have a strong relationship. This year, our IAH Base team is sponsoring a team from MIAT-Houston, the Chix Fix are working with students from West L.A. College, and the Line Maintenance team members are mentoring students from PIA-Youngstown, Ohio.

As all the teams gathered for a group training, practicing and socializing session in Houston in late March, a number of students nearing graduation were interviewed and went through practical exams at our Tech Ops Recruiting Center. Many of them accepted employment offers, said Line Maintenance and Tech Ops Recruiting Senior Manager Fortin.

The AMC has always been a great place to recruit aviation students as well as experienced technicians from the military and industry. Our team members are always sought out by conference attendees to get the inside scoop on working at United. Our all-female Chix Fix team, who have competed since 2018, are credited with greatly raising awareness of United opportunities for women.

Just as the Chix Fix have inspired other companies to field all-women teams, more and more teams are also going co-ed, including our IAH Base team, which is proud to include a woman this year, Avionics Technician Julie Thompson. They have a history of strong showings in the MRO division of the AMC and are certain to be a favorite to win it all this year. In fact, the consensus after training in Houston, said Line Maintenance VP Rodney Luetzen, was that United teams should finish 1-2-3, or even better, in a three-way tie for first place.

“American’s six teams can finish 4-5-6-7-8-9, that would be all right with us,” Rodney joked.

Every team will be keeping a close eye on our Line Maintenance team, which evolved from the CLE (Cleveland) Line team that dominated the AMC for three straight years until the pandemic hiatus. The team now is made up of both CLE and ORD technicians, and is coached by three-time champion team member Jack Waldeck.

The AMC is put on by the Aerospace Maintenance Council, a non-profit with the mission of promoting and celebrating aviation maintenance professionals. United Tech Ops Senior Vice President Tom Doxey was recently elected to its board of directors. The executive committee led by the Hon. John Goglia, a former United employee and the only FAA-certificated mechanic to receive a presidential appointment to the National Transportation Safety Board.

The SFO Engine, Landing Gear, Remanufacturing, Harness, and Accessories Shops have completed initial certification under the AS9110 Quality Management System for Aviation Maintenance Organizations.

Our Technical Operations Recruitment Center (TORC) has been very successful in offering an all-in-one experience for prospective technicians, and this spring, we’re taking TORC on tour to make it even easier for applicants from a number of institutions where we are actively recruiting for the next generation of aircraft maintenance professionals.

Anticipating the hiring needs we are now facing, Tech Ops established TORC at the Operations Center (OPC) in Elk Grove Village, Ill., in 2017. It centralized and streamlined the entire process. Applicants could be flown in if necessary, were interviewed and underwent practical testing, and top candidates received immediate offers. When we closed the OPC facility last year, we moved TORC to IAH.

Now, as many aeronautics school classes are nearing graduation, we decided to streamline the process even further by bringing TORC to schools where we already have a strong relationship and that have produced many strong candidates for us in the past, said Line Maintenance Director Don Klaus, who is overseeing the recruitment effort in partnership with Human Resources.

Earlier this month, we conducted a two-day TORC on Tour session at the Pittsburgh Institute of Aeronautics (PIA). Tech Ops Hiring Programs Senior Manager Matt Fortin said we met with 36 students who went through interviews and practical evaluations, and made a number of on-site offers.

“We also had a number of other students who heard from their fellow students that United was on site, and as a result we had an additional seven students drop in asking if they could participate,” Matt said. “We had a very tight schedule but were able to interview them, and we’ll bring some of them to Houston for their practicals. In all, we stand to make 34 offers from this one event.” The students from PIA are all expected to graduate no later than June.

“This is exactly what we aim to accomplish with our school partnerships and by taking TORC on the road,” Don noted.

“We made some young, future United technicians very happy with on-the-spot contingent offers,” said EWR Hub and Region Line Maintenance Managing Director Norm Kopicko.

Matt thanked Norm, Don and everyone else who took part over the two days, meeting with and interviewing applicants, answering questions about working at United and serving as proctors during the practicals. Others at PIA included: SFOHR Senior Recruiter Kathi Rhodes, IADMM Supervisor Travis Allee, EWRMM Shift Manager Rich Dressler, ORDMM Supervisor Matt Murray, EWRMM Supervisor Jimmy Chan, EWRHR Recruiter Diane Williams, WHQHR Senior Sourcer Maria Baldonado, and IAHHR Recruiting Representative Eric Morales.

Tech Ops hopes to onboard about 1,100 technicians and 300 other employees (in areas such as stores, GSE/facilities maintenance, training and tooling) by the end of 2022, and expects similarly high targets each of the next five years and beyond as the operation grows to support the airline’s projected growth via United Next.

The SFO Engine, Landing Gear, Remanufacturing, Harness, and Accessories Shops have completed initial certification under the AS9110 Quality Management System for Aviation Maintenance Organizations.

The AS9110 certification is a requirement for the U.S. Air Force F117 engine contract with Pratt & Whitney and Boeing, and is the most difficult of the ISO Aerospace Standards to achieve. Supply Chain Planning VP Tarundeep Suri called completion of this certification, “A testament to the professionalism and expertise of the SFO team.”

This effort was led by SFO Compliance and Safety Senior Analyst James Elliott and SFO Inhouse Maintenance Compliance Director Steven Templin. At the beginning of May, the AS9110 lead external auditor visited SFO for the first time to conduct a two-day pre-audit assessment. The lead auditor’s report formally recommended that we move forward with the two-stage certification audit.

Stage 1 was completed during the last week of July. The Stage 2 Audit included five-and-a-half days of auditing, conducted by two auditors during the last week of September. Led by Steven and James, the team took action to address the audit findings; identifying the root causes and the required actions to take. Steven and James summoned the expertise of many technicians, including Robert Briggs and Roberto Isola, and a number of others who did a lot of heavy lifting with tool control improvements – including Rosann Boots, Roy Davis, John Hill, Mark Milani, Chuck Oliver, Mary Rinaldi and Tim Tobias.

On Dec. 1, 60 days after the close of the Stage 2 audit, the lead auditor returned to verify the implementation and effectiveness of the corrective actions. Given the size of the SFO Engine and Landing Gear Shops, the auditor was very surprised and pleased with the amount of work we were able to accomplish within 60 days. At the end of his visit, the lead auditor was quite satisfied that we met all of our commitments for corrective actions and officially recommended the shop for certification.

“This was an exemplary team effort, where all leaders and technicians aligned to overcome the challenges to attain the arduous AS9110 certification,” said Tarundeep.

On Tuesday, we marked a major milestone for United Airlines – with the opening of our brand-new, state-of-the-art United Technical Operations Center (UTOC), all our Tech Ops teams at the hub are in the same location. This also means that for the first time since the merger, we don’t have any split operations at any hub or line station.

The 27-acre UTOC comprises much more than a hangar, but, wow, what a hangar – state of the art, environmentally friendly, designed for growth, and big enough for two widebodies or up to six narrowbodies at a time. It’s located on the site of the hangar-less United East complex that was obsolete but had the benefit of being located relatively close to the terminals. Our somewhat newer West Hangar facility, which we vacated Oct. 31, was more than a mile away.

In addition to the behemoth of a hangar, we have a new parts warehouse, Ground Service Equipment shop with 15 bays, an Engine Build-Up shop, other shops and offices, a new home for the Move Team, training rooms and break rooms, all located just off Century Blvd., next to the United Cargo facility. More than 500 employees call the UTOC their work home. More than 800 people worked on the construction, which began in early 2019. It’s all environmentally low impact and engineered to be safe in earthquakes and to handle once-in-a-generation floods.

At a celebratory ribbon-cutting event on opening day, LAX Hub Managing Director Jonna McGrath told the assembled employees, guests and media that, “This project and the nearly $1 billion investment United has made at LAX have allowed us to grow our presence in Southern California and offer a best-in-class experience for our customers.” Set against a backdrop of a Boeing 787-9 and the active airfield, the speakers had to pause regularly for takeoffs. “It’s nice to be interrupted so much now that the airport is busy again,” said Jonna.

“I’m so excited that our professionals here have this great new home,” said Tech Ops SVP Tom Doxey. “We’re investing in our people – employees and the customers we fly every day. The investments we are making to our product and the new aircraft we are adding to our fleet in coming years will also create new jobs, here and at other locations in our system.”

Maintenance Operations VP Rodney Luetzen, who started as an aircraft technician and spent several years at LAX, said the UTOC is “more than a hangar; it’s a community,” and thanked a number of employees who played crucial roles in getting it built, including Tom, who was a VP in Finance when the project was approved. Rodney also thanked the LAX Tech Ops teams, especially Director Fabio Maietta and Senior Manager Reza Asadifar, and Corporate Real Estate Senior Project Manager Armando Hernandez.

“To our technicians and others here who worked in multiple locations for so long, welcome to your new home,” said Rodney.

The UTOC opening is but the latest of a string of capital projects that have improved and increased the Tech Ops footprint in recent years, so the department can provide an even stronger network to support the growth of the airline. We just announced that we will renovate a former Air National Guard hangar in PDX. Last year, we built a new hangar for TPA (Tampa, Fla.) and opened the huge new Hangar X, centerpiece of our UTOC in IAH. A few years earlier, we built the first hangar for United at the IAD hub, and added a new widebody hangar to our complex at EWR.

Also speaking were Justin Erbacci, CEO of Los Angeles World Airports, and Gabriel Eshagian, commissioner for the Board of Airport Commissioners. “I’ve presided over every ribbon-cutting ceremony involved in your $1 billion LAX investment,” said Gabriel. “I was here for the groundbreaking, and I’m absolutely amazed at what I’m seeing here today.”

We have successfully completed our first 787-8 landing gear replacement! A/C 0906 was the first 787 in North America to have its landing gears replaced.

The gear replacement was performed at our maintenance base in San Francisco by a team of specialized technicians led by SFO Maintenance Supervisor Ken Lewinsky and under the guidance of Principal Engineer Tariq Siddiquie.

The SFO Base Maintenance Line plus (+) organization also requested the technical support of Maintenance Training. Instructor Jay Juman was on site to provide guidance for the operational checks and technical support for some issues that were present with the aircraft, including facilitating proper flap extension during docking procedures.

In partnership with Boeing, United Airlines elected to be among the first operators to remove one of our 787 landing gears several years early to inspect the condition of certain key components. This early removal supports an effort to formalize the landing gear overhaul interval from 10 to 12 years for the worldwide fleet. Huge thanks to teams from SFO maintenance, maintenance training, planning, and engineering for their expert collaboration on this gear change.

The Airframe team at IHC, the maintenance base at IAH, inducted our very first 737 MAX for its first heavy maintenance check this week, a significant milestone for our Tech Ops teams, for the base and for the fleet.

A number of things aligned to make this an extra-special occasion. The first MAX aircraft we took delivery of, a/c 7501, was due for its first heavy check, and others from the initial group of 14 aircraft will also be coming to IAH over the coming months for theirs. The aircraft will be worked by our IHC Airframe team that now includes the employees and shops that used to be at HOU (Houston-Hobby). Airframe now has three contiguous hangars at IHC, plus a brand-new shops building to provide exceptional support for the maintenance teams. Nearby is the massive Hangar X (Line Maintenance) plus its annex with engineering and other support teams.

“The Houston base has been a Center of Excellence for the 737 fleet for decades, and the MAX represents the future of heavy maintenance for Houston,” said Airframe Overhaul & Repair Senior Manager Steve Minasi.

“It worked out so well, timing-wise, that this first MAX check coincided with when we’re finally able to start having gatherings like this again, and we can thank our employees for the great work they do as a team,” said Airframe Overhaul & Repair Director Bonnie Turner.

Tech Ops Planning and Strategy VP Kurt Carpenter, who oversees Airframe, was on hand to meet and thank employees on all three shifts June 9-10; he was joined on June 10 by Tech Ops SVP Tom Doxey, and IAH Hub VP Phil Griffith, who recently left his role as Tech Ops Supply Chain VP, also dropped by.

Tom talked with a number of technicians who formerly worked at HOU, thanking them for their support in the long process that led to the move out of the aging facility finally taking place last fall.

“Coming from Hobby, I can say the new facility here is great,” said Airframe Supervisor Anthony Stavinoha. “It’s a welcome change! The new (iPad) technology is very useful as well, and allows us to be more efficient.”

Sheet Metal Lead Technician Dennis Luces also expressed his satisfaction with the new location. “In addition to a lot more room to work and plenty of breakroom space to engage and interact with team members, our new facility has a dedicated composites shop. The iPads are also a welcome change, enabling us to do our work in real time.”

United Airlines today named Tom Doxey senior vice president of Technical Operations, overseeing the carrier’s maintenance operations; ground service equipment and facilities maintenance; supply chain; technical services and planning and strategy. Doxey most recently served as vice president of Technical Operations and under his new role will report to United’s Chief Operations Officer, Greg Hart.

“I couldn’t be more excited to have Tom lead the Tech Ops team,” said Hart. “Leveraging his experience leading finance for operations and his passion for people, I know the team will continue their string of record performance under his leadership.”

Doxey joined United in 2016, assuming the role of chief financial officer for operations, overseeing teams that provide financial and analytical support to United’s operations groups, including Tech Ops. Prior to joining United, Doxey served as vice president, fleet and corporate finance at Allegiant, where he was responsible for all aircraft and corporate finance transactions, materials planning, stores, fleet planning and the financial management of airframe and engine heavy maintenance programs. Doxey started his airline career at US Airways, where he held various roles in financial planning and analysis.

Doxey holds a bachelor’s degree from Brigham Young University and an MBA from Arizona State University.

United Technical Operations is pleased to announce it is partnering with Fortress Transportation and Infrastructure Investors LLC (FTAI) Aviation for PW4000-94" overhauls. FTAI Aviation purchased surplus engines from United and chose United’s MRO Services for the program. This partnership will foster growth for our Engine MRO and build a platform for success throughout the coming years. United has already inducted the first three engines into its San Francisco facility.

"FTAI Aviation is a wonderful partner and customer for us to build our MRO brand as we ramp up our commercial third-party business." – Mark Eldred, VP, Base Maintenance

"United Technical Operations was a great choice for our immediate PW4000 maintenance needs, and we will be looking to them for future work as well." – Joe Adams, CEO, FTAI

Every year, aircraft maintenance technicians from around the world are invited to compete in a two-day tournament against the best of the best and, until now, no team of technicians had ever achieved the goal that eludes even the New England Patriots – the “three-peat.”

When it comes to maintenance, the entire industry now knows that Cleveland rocks. The United CLE Line Maintenance technicians, who trained in T-shirts with a target on the back, were crowned the champions of the Aerospace Maintenance Competition in Atlanta, posting the best scores of more than 80 teams to retain the William O’Brien trophy.

In many ways we dominated the 2019 AMC, held each year as part of the MRO Americas conference. United entered four teams again this year, and the Base Maintenance team of technicians from the Houston and San Francisco Base Maintenance Centers took third place in the MRO (maintenance, repair and overhaul) division. The vaunted Chix Fix team and the first-time team fielded by ORD Line Maintenance also won prizes in individual events.

“You have all made us very proud at United in so many ways,” Maintenance Operations VP Don Wright told the assembled teams at a celebration dinner following the awards ceremony on April 12. “You’re the best ambassadors not only for United as a great place to work, but also the professionalism and skill that you’ve displayed over this past week shows the industry the extraordinary talent that we have at United.”

“Not everybody can appreciate how hard it is to win any one event,” Base Maintenance VP Mark Eldred noted. (The Base team took five, most of any team.) “All of our teams medaled, which is amazing, and throughout this entire conference I kept hearing from people who were very impressed with all the team members they encountered.”

Former United technician and NTSB member John Goglia, recognized as the godfather of the AMC, closed the awards ceremony by thanking United and the other participants who are taking steps to recruit more women technicians and called our Chix Fix pioneers in the effort. United recruitment employees staffed a table adjacent to the AMC competition area and noted a steady stream of would-be applicants coming by who related that they were drawn to United by watching and talking to not only the Chix Fix but all of the United teams who demonstrated unrivaled professionalism and collegiality.

“In more than 30 years at United, I have to say this is not only the most fun thing I’ve ever done, it may be the most worthwhile, too,” said ORD Aircraft Inspector Polly Delaney, a two-year veteran of Chix Fix. “We’ve not only got the undisputed best team in the industry in CLE, but with all our AMC teams, and the big presence we have at the MRO Americas conference, we’re really sending a positive message about Tech Ops and about United.”

Technical Operations and Digital Technology employees who played critical roles in the more than two-year effort to develop and deploy the United Tech mobile app accepted well-deserved acclaim from industry peers March 14 at the Aviation Week Network’s Laureate Awards ceremony in Washington, D.C.

Our program to put more than 6,000 iPads into the hands of Line Maintenance technicians and inspectors won the Commercial Aviation/MRO (maintenance, repair and overhaul) award and received a loud ovation when announced at the awards dinner.

Tech Ops and Digital Technology officers Kris Bauer, Jason Birnbaum, Kurt Carpenter and Don Wright joined nearly 20 representatives of their departments who have been integral to the success of the project. Many of them have been involved since the beginning on projects such as the electronic log book.

Don, who got this program started in Line Maintenance in earnest more than two years ago, thanked some of the “champions” who initially came together from hubs and stations in early 2017 with long wish lists of things they wanted the new technology to do for them.

“Every single one of us would have said you were crazy if you said two years ago we could have anywhere near this kind of impact by now with United Tech,” said SFO Lead Line Technician Mansur Zia, one of the Tech Ops Mobility champions who is credited with making the program such a success through his advocacy for change.

“Without the partnership between our groups, and the Tech Ops champions being integrated with the Digital Tech team, I doubt that this would have been possible,” said Applications Development Director Helon Hammond.

Helon and Tech Ops Planning and Strategy VP Kurt Carpenter accepted the trophy, which may now go on tour to the stations where iPads are being used every day. Kurt, who joined United to lead this program from the business side in mid-2017, said Tech Ops Mobility was as good an example of interdepartmental collaboration as he has ever seen in his many years of airline experience.

“They have certainly all earned this recognition,” Kurt said.

Yolanda Gong had been awaiting this challenge all day. As fellow competitors looked on, she took a pipette and carefully removed lubricant from a jet engine, then injected it into a handheld machine to analyze its viscosity, a process that aircraft maintenance technicians use to gauge an engine’s health. She moved quickly with a steady hand and steely confidence, and if you watched her closely, you would have caught a glimpse of who she was, back in a laboratory in another life, when she was living someone else’s dream.

Each participant was allotted 15 minutes, which was 11 minutes and 44 seconds longer than Yolanda needed. It was the fastest time recorded at last spring’s Aerospace Maintenance Competition – which draws civilian, military and student technicians from all over the country, all vying for coveted bragging rights – where she captained the team from West Los Angeles College. The oil analysis was just one event in which she and her teammates competed over the course of three days, during which Yolanda impressed a lot of people, including the members of our all-female “Chix Fix” team, who were also there.

“When I saw her on stage receiving awards, I knew Yolanda would make a good addition to the United team, not to mention a strong competitor for Chix Fix,” said SFO Airframe Overhaul and Repair Managing Director Bonnie Turner. “Her professionalism and talent caught my attention that day, and I’ve been thrilled to have her as a technician.”

In September, after earning her airframe and powerplant license, Yolanda was hired at the San Francisco Maintenance Base as an Aircraft Interior Repair Tech. To her, meeting Bonnie and the women of Chix Fix was serendipity; a chance encounter that led to a life-changing opportunity. But that’s not entirely true. She might have been in the right place at the right time, but make no mistake – Yolanda’s success is a byproduct of effort and ability. She’s doing what she was meant to do, though it took her traveling an unconventional path to get to this place of self-realization.

Growing up, Yolanda’s mother and father steered her toward a more genteel career. In their minds, she would become a doctor or a lawyer. In other words, something “suitable for a woman,” a notion that rankled their mechanically-inclined daughter. In the end, Yolanda settled on medicine for many of the same reasons she would eventually move into aircraft maintenance.

“I was interested in how the body works,” she said. “I like systems and puzzles, looking at causes and effects.”

Yolanda completed her pre-med studies at the University of California, Los Angeles, but when it came time to take the MCAT and apply to medical school, she found herself at a crossroads. It was then that she realized her own goals were more important than the ones someone else had set for her, and she certainly wasn’t going to let something like expectations based on gender stand in her way. After some soul searching, Yolanda enrolled in West Los Angeles College’s aviation technology program, where she was one of only four women in a class of around 30 students.

“I’ve always wanted to know how to use tools and do things for myself,” said Yolanda. “And I never paid attention when someone told me, ‘You can’t do that.’ I’ve always said, ‘Well, let me try.’”

Over the past few months since graduating, Yolanda has been a rising star at United. She’s even set to return to the Aerospace Maintenance Competition in April, this time as part of team Chix Fix, where she and her colleagues plan to show what they can do.

“It’s likely there will be a shortage of technicians soon,” she said, “so I want to make sure women know opportunities are here for them. Don’t let anyone tell you what you can or can’t love. The only thing stopping you from doing what you want is your belief in yourself. It’s incredibly freeing when you stop caring what other people think and just do it.”

In honor of Women’s History Month, we are profiling women who are making an impact here at United. Look for more stories like this one throughout March.

Many United employees thought this day might never come – after years of hoping for a world-class facility to replace our aging maintenance complex on the east side of the LAX airfield, we broke ground February 28 for a brand-new Technical Operations Center.

The complex will feature a new hangar with room for two widebodies at a time or six narrowbodies plus parts stores and shops, including an engine buildup shop. There will be a connected ground service equipment and facilities building, meaning that for the first time since 2010, the whole Tech Ops team will be under the same roof.

EVP and Chief Operations Officer Greg Hart looked around at the crowd of employees, airport representatives and guests who gathered for the ceremonial ground-breaking and noted how many Tech Ops colleagues at LAX were sons and daughters of United employees who had lived through numerous false starts in the past.

“I know that at United, we’re known for using things to their full extent as much as we can, but with this, we may have taken it too far,” Greg said to laughter. “For so long, people here have been asking, ‘Is this ever going to happen?’ I’m here to tell you today – this is going to happen.”

The event was held adjacent to the 1940s-vintage east side buildings the new complex will replace. A brand-new 787-10, perched on the other side of the stage, was the appropriate backdrop, since while the LAX Tech Ops team can handle every aircraft in our fleet, they specialize in servicing our newest fleet.

LAX Airport Operations Managing Director Lori Augustine noted how, thanks in large part to Tech Ops’ performance, the hub consistently beats the competition in the race to be No. 1 among carriers at the very competitive hub.

“This will be a state-of-the-art facility for a state-of-the-art operation,” Lori said. Combined with the recent renovation of Terminal 7 and the United Club, and the opening of the Polaris Lounge, she added that “We’re investing nearly $1 billion in Los Angeles. We’re here to stay,” she said to cheers.

LAX Avionics Technician-Line John Woodruff, one of the frontline employees who joined the executives for the symbolic groundbreaking photo opportunity, said like many of his colleagues, he looked forward to working in the new complex after it opens in 2020.

“We’ve been hearing about this, and hoping for it, for years and years,” John said. “Now that it’s actually going to happen, it’s going to be amazing what we can do in a world-class facility where we’ll be all together and so much closer to the terminal.”

LAX Line Maintenance Managing Director Fabio Maietta said in addition to vastly reducing aircraft movements and the related back-and-forth of people and parts, having the whole Tech Ops LAX family in one place will be a major boost for the whole operation.

“Just what it will do for our ability to communicate and respond more quickly to operational needs is something that cannot be underestimated,” Fabio noted. “I’m proud of how well we’ve come together even though we’re in two locations more than a mile apart, and know when we’re together, we’ll be able to provide even better customer service.”

“This new Technical Operations Center reiterates United’s commitment to Los Angeles and all of California,” said our President of California, Janet Lamkin. Corporate Real Estate and Environmental Affairs VP Gavin Molloy was also on hand to thank his team, particularly Senior Project Manager Armando Hernandez, for getting the project to this stage. Demolition on the old east buildings is expected to start this April.

Congratulations to the team in Shop 274, part of the Component Overhaul and Repair department at the San Francisco Maintenance Center, which overhauled its 100th Boeing 737 engine inlet since insourcing the work three years ago.

During the early stages of our Base Maintenance Transformation, in January 2016, the team was tasked with developing an overhaul program to enable us to bring the work in house. Technicians Dan Sutter, Bill Kumpu (now retired) and Martin Dergan got to work on this with the help of Components Engineer Ricardo Rodriguez.

Martin recalled, “The first inlet we received was one that had been deemed BER, or Beyond Economical Repair.” But with the help of Technician John Cicero in Composite Shop 273, he was able to develop a method of “reskinning” the acoustic panels and saved the inlet from the scrap heap. That saved United the cost of a replacement inlet and showed that the shop could overhaul the inlets to serviceable condition economically.

“Since that time, we have overhauled 99 other inlets,” Martin said. “We have run this program with a lower average cost compared to our previous vendor’s and have achieved an industry-leading turnaround time of 11 days.”

“Base Transformation was a challenging time for the Components shops,” recalled Component Overhaul and Repair Managing Director Bill Fulton. “We were exiting non-core work, relocating people between departments and faced a lot of uncertainty. But we knew we would be successful insourcing the 737 inlet work.”

In addition to the technicians and engineers in the shop, Bill said the effort included the Base Maintenance Operations team, Vendor Management, Procurement and other groups. In the end, Bill said, “The shop technicians’ innovativeness and tenacity proved that we can be a top-tier supplier to United Airlines. They made this happen using their skills and heart.”

Component Overhaul and Repair is looking into the possibility of taking in third-party 737 inlet work and developing a program for the inlets on the Rolls-Royce RB211 engines found on our Boeing 757s.

In addition to the 737 inlets, we have insourced many other components since 2016, including avionics, thrust reversers, inlet cowls and flight controls, to name a few.

The TPA (Tampa, Florida) Airport Board of Directors on February 14 overwhelmingly approved United’s ground lease for a new Technical Operations hangar, which will have room for two Boeing 737 MAX aircraft plus adjacent ramp space. Work is expected to begin this June, with the hangar fully operational by mid-2020. It will be erected on a 9.5-acre parcel of land to the east of the terminal.

TPA Line Maintenance Senior Manager Dan Sonego said all work at TPA is now done at the gates, so having a dedicated, state-of-the-art hangar will greatly enhance our maintenance capabilities at the station. The new facility will also offer improved safety systems, break rooms, locker facilities and storerooms, he said.

Corporate Real Estate and Environmental Affairs VP Gavin Molloy thanked his team for their work that led to us clearing this final hurdle before work can begin, particularly Airport Affairs Regional Manager Gregory Kozak for negotiating the terms of the lease agreement.

“Over the past two years, moving some scheduled maintenance checks to stations such as TPA has helped contribute to Tech Ops’ improved reliability,” said Tech Ops SVP Kris Bauer. “A number of other significant infrastructure investments are in the works.”

Tech Ops plans to break ground later this month on a new hangar at LAX, and a massive hangar that is the centerpiece of the new United Tech Ops Center in IAH is set to open before the end of this year. We also have hangar construction or renewal projects taking place at ORD and PDX (Portland, Oregon).

As Aviation Week & Space Technology announced, “United developed a mobile app that connects its 6,000 line mechanics with everything they need to diagnose issues and get out-of-service aircraft flying again—all without touching a paper manual or a desktop computer.”

“This award is a testament to the dedication and teamwork of so many people in Tech Ops, in Digital Technology and other departments to bring us to this stage,” said Tech Ops SVP Kris Bauer. “We are leading the industry in this area, and it’s gratifying to be recognized with such a prestigious award.”

The majority of technicians and inspectors embraced Tech Ops Mobility quickly, largely because they were the primary designers, Maintenance Operations VP Don Wright noted. “The apps and user interfaces were developed by and specifically for the front-line teams using the tools in the field,” Don said.

Kris also pointed out that while we have deployed iPads across Line Maintenance, the program is continually evolving, with improvements based directly on user feedback, and we are in the early stages of expanding mobility into other areas, such as parts of Base Maintenance. We are also working on a wide range of other modernization projects that will improve user experiences and interfaces in virtually every corner of Tech Ops.

“In many ways, our digital transformation is just beginning,” Kris said. “This is a major investment in the future of Tech Ops and how we can contribute to United’s success.”

The winners of the 62nd annual Laureate Awards will be honored on March 14, 2019, at the National Building Museum in Washington, D.C. At that time a Grand Laureate in each of the four categories will be named from among the winners, so United is eligible for that top prize in the Commercial Aviation category.

Thousands of our friends and relatives partied for five solid hours on the ramp, in the hangars and in the shops Sunday, October 7, as the San Francisco Maintenance Center celebrated its 70th anniversary during the 13th annual Family Day. The event gives visitors a rare glimpse at what our employees get to see – and do – every day.

For our visitors, there were awe-inspiring sights at nearly every turn. With all the attractions competing for their time, from plane pulls to ziplines to paper airplane contests to checking out the Patriots Jet Team and vintage cars, many visitors chose instead to wait in line for an hour or more just to walk through a Boeing 787 and take selfies in the cockpit.

They also enjoyed close-up looks at an unsheathed GE90 jet engine and various landing gear sets, and they crowded around a Boeing 737 to catch three showings of something most people never, ever see close-up – the landing gear lowering and retracting into the fuselage again.

Out on the ramp, everyone stopped to watch as our Boeing 777-300 lifted off from SFO and climbed directly overhead on its way to the San Francisco Fleet Week Air Show and did so again when the Patriots departed in formation for their segment of the show.

Our commitment to safety was evident, as was our core4 standard of caring. In every corner of the huge base that was open to visitors, our employees were proudly showing what we do to their kids and friends and neighbors and in-laws; performing in the bands that entertained the crowd; showing that an all-women team of technicians, the Chix Fix, has what it takes to compete on an international level; and getting others involved in the community and volunteer activities that make us exemplary corporate citizens. United We Care and our Special Olympics partners were well-represented, the latter with a group of a dozen athletes.

President Scott Kirby told the crowd during the opening ceremonies, “Here in San Francisco, this is a crown jewel for United Airlines and something we take seriously. I want to thank you all for what you’re doing for United and for what you’re doing to make an already vibrant community even stronger.”

Of course, Family Day – a massive undertaking – would not exist without thousands of hours put in by volunteers, who were publicly recognized for their efforts by Base Maintenance Vice President Mark Eldred in his opening ceremony remarks and throughout the day as he walked the event and thanked people personally for their roles.

The volunteer corps expanded way beyond Tech Ops and the base support organizations – Airport Operations, Flight Operations and Inflight Operations all sent large cadres of helpers, many of whom staffed the aircraft we had open for cabin and cockpit tours. If that weren’t enough, the 777 BBQ team came in from Houston.

As for dependability and efficiency, the base has been focused since its founding in 1948 on keeping United on time, safe and fully compliant with the highest standards. And the Maintenance Center and Tech Ops as a whole are taking huge strides toward becoming more efficient, not only servicing United’s mainline fleet but also competing as a global provider of MRO (maintenance, repair and overhaul) services.

“I am incredibly proud of all we have accomplished at this base over seven decades, and I think our best years are ahead of us,” Mark said. “We obviously can’t open our doors like this often, but thanks to all the hard work our volunteers put into this event, we get to show off once a year, and I hear nothing but good things from our guests.”

Of course, Family Day – a massive undertaking – would not exist without thousands of hours put in by volunteers, who were publicly recognized for their efforts by Base Maintenance Vice President Mark Eldred in his opening ceremony remarks and throughout the day as he walked the event and thanked people personally for their roles.

The volunteer corps expanded way beyond Tech Ops and the base support organizations – Airport Operations, Flight Operations and Inflight Operations all sent large cadres of helpers, many of whom staffed the aircraft we had open for cabin and cockpit tours. If that weren’t enough, the 777 BBQ team came in from Houston.

As for dependability and efficiency, the base has been focused since its founding in 1948 on keeping United on time, safe and fully compliant with the highest standards. And the Maintenance Center and Tech Ops as a whole are taking huge strides toward becoming more efficient, not only servicing United’s mainline fleet but also competing as a global provider of MRO (maintenance, repair and overhaul) services.

“I am incredibly proud of all we have accomplished at this base over seven decades, and I think our best years are ahead of us,” Mark said. “We obviously can’t open our doors like this often, but thanks to all the hard work our volunteers put into this event, we get to show off once a year, and I hear nothing but good things from our guests.”

All afternoon, teams tugged the “retro” United livery Airbus A320 in two categories of plane pulls – teams composed of our visitors pulled for fun and bragging rights, and other teams made up of United employees did so for the right to represent SFO in the finals of the employee Plane Pull competition.

While the retirement of the 747 served as the centerpiece of last year’s event, this year’s theme was the long and storied history and bright future of the SFMC. Most attendees at some point made their way over to the widebody Dock 2, where we staged a popup museum highlighting the history of the base, including continuous showings of a video that in 20 minutes neatly told the story of the base and its people – over the years, at least 30,000 technicians and related employees have worked there on the maintenance, repair and overhaul of our aircraft and their components, in addition to many customer aircraft.

The video, as well as the enlargements of historical photos that adorned the space, were done by a sheet metal technician from the SFO Airframe Overhaul and Repair department, Clark Cook, who also just happens to be an accomplished photographer and videographer.

Also in Dock 2, some of our best technicians who just happen to be women – Chix Fix Team – demonstrated some of the events they mastered to qualify for the Aerospace Maintenance Competition; they are in training for their second try at the title in the spring of 2019. During the day, they had a steady stream of spectators and well-wishers, no doubt including young girls and boys who now dream of one day becoming United technicians themselves.